The natural choice

Produktinformasjon

E470 er et lavkarbonstål som er mikrolegert med vanadium og hvor betegnelsen "E" refererer til rørformen. Stålet har en betydelig høyere styrke enn emnerør i vanlig konstruksjonsstål type E355. Til tross for den høye styrken opprettholdes god sveisbarhet, og stålet er lettbearbeidet. Lagerprogrammet består av emnerør i stål E470 og delvis i stål 280. Materialrør i 280 er preget av smalere analyse, bedre mekaniske egenskaper og finere toleranser enn de tilsvarende rørene i E470.

E470 i form av varmvalsede sømløse rør er standardisert i SS-EN 10294 - 1. Den nærmeste SS-betegnelsen er 2142. 280 er lik E470, men er preget av smalere kjemisk analyse. Strekk- og bruddgrensen for E470 varierer mellom henholdsvis 470 - 430 MPa og 650 - 500 MPa, avhengig av veggtykkelse. For 280 er de samme styrkeverdiene 5 til 10% høyere og utvidelsen er bedre.

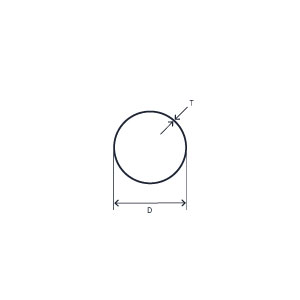

Toleranser for ytre diameter og vegg for varmvalsede rør i E470 er definert i SS-EN 10294 - 1. 280 rør har noe strammere toleranser. En viktig parameter er dimensjonene, både eksterne og interne, som kan oppnås etter maskinering. Dimensjonene som er oppnåelige er angitt i SS-EN 10294 - 1 for både ekstern og intern sentrering. Betegnelsene som er gitt gjelder ytre sentrering og samsvarer med de gitt SS-EN 10294 - 1. De første 2/3 tallene angir den største garanterte ytre diameteren mens de siste 2/3 gjelder den laveste garanterte innvendige diameteren. Disse garanterte dimensjonene gjelder over en lengde på 3 ganger ytre diameter eller 200 mm, avhengig av hva som er minst. For innvendig sentrering er de garanterte dimensjonene etter bearbeiding generelt noe mindre.

SS-EN 10294 - 1 foreskriver også retthet med høyde på buen maksimalt 0,001 ganger lengden.

Hvis man ønsker garantier for skårslagsseighet, kan både E470 og 280 normaliseres med gode resultater. Imidlertid kan en viss reduksjon i både strekningen og bruddgrensen forventes etter en slik varmebehandling.